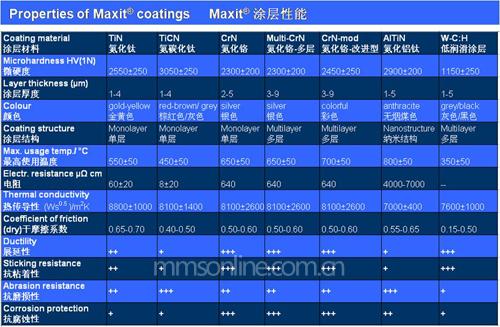

认识MAXIT® 涂层

——Get to know MAXIT® coatings

MAXIT ®coatings help their mould customer maximize their profit.

MAXIT ® 涂层帮助模具客户实现最佳收益

Fast turn-round time, reduced use of consumables and low maintenance are all important requirements for any mould & die user.

快速运转,低消耗,低维护是任何模具用户重要的追求。

Thin-film technology has firmly established itself as an effective method for reducing abrasive wear, surface pickup, galling, friction, and both chemical and thermal attack. These coatings help to reduce tooling costs, increase productivity and product surface quality.

薄膜技术已被确立为减少磨损,表面粘结,磨伤,摩擦,化学侵蚀和热侵蚀的有效方法。这些涂层可以帮助降低模具成本,提高生产力和产品表面品质。

Sulzer Metco has several decades of experience in Mould & Die industry. Its combined application of plasmanitriding and PVD hard coating represents a further particularly efficient tool for reducing abrasion, cold bonding when forming metals as well as corrosion and adhesion when processing plastics or elastomer materials.

苏尔寿美科在模具行业有数十年的经验。其特有的等离子氮化与PVD涂层组合处理工艺为解决金属成型加工中存在的磨损,冷焊问题和塑料与热塑性弹性体加工中存在的腐蚀与粘附问题提供了有效的解决方案。

声明:本网站所收集的部分公开资料来源于互联网,转载的目的在于传递更多信息及用于网络分享,并不代表本站赞同其观点和对其真实性负责,也不构成任何其他建议。本站部分作品是由网友自主投稿和发布、编辑整理上传,对此类作品本站仅提供交流平台,不为其版权负责。如果您发现网站上所用视频、图片、文字如涉及作品版权问题,请第一时间告知,我们将根据您提供的证明材料确认版权并按国家标准支付稿酬或立即删除内容,以保证您的权益!联系电话:010-58612588 或 Email:editor@mmsonline.com.cn。

- 暂无反馈