加工中心编程之加工中心编程实例1

加工中心编程实例

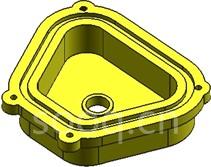

【例6-10】 在加工中心上加工图6-31所示的壳体零件,材料HT200。零件底面、圆孔及孔止口面已加工完成,现要求:铣顶面保证 尺寸, Ra3.2m。铣槽 , Ra6.3m,一次加工完成。钻攻4M10螺纹孔及孔口倒角。

该零件以底面孔和圆孔为主定位面,侧面采用定位螺钉为辅助定位,圆孔止口面为夹紧面。一次装夹后完成所有的加工内容。加工工艺与刀具如表2-32、表2-33。 工件坐标系设在工件中心,且离工件底面上方70.1mm处。槽中心线各基点的坐标为:a(60,87)、b(102.77,20.52)、c(63.67,-65.34)、d(30,-87)、e(-30,-87)、f(-63.67,-65.34)、g(-102.77,20.52)、h(-60,87)。

O1002;

N010 G40 G80 G17;

N020 G91 G30 X0 Y0 Z0 T01;

N030 M06; 换面铣刀

N040 G00 G90 G54 X0 Y0 S300;

N050 G43 Z0 H01 M03 T02;

N060 G01 Z-10.0 F30;

N070 Y87.0 F60;

N080 M98 P0001;

N090 G00 Z100.0;

N100 G91 G30 X0 Y0 Z0;

N110 M06;换中心钻

N120 G00 G90 G54 X50.0 Y-100.0 S1250 ;

N130 G43 H02 Z100.0 M03 T03;

N140 G99 G81 Z-15.0 R-7.0 F100;

N150 X105.0 Y90.0;

N160 X-105.0;

N170 G98 X-50.0 Y-100.0;

N180 G80;

N190 G91 G30 X0 Y0 Z0;

N200 M06; 换φ8.5mm钻头

N210 G00 G90 G54 X50.0 Y-100.0 S600;

N220 G43 Z100.0 H03 M03 T04;

N230 G99 G81 Z-30.0 R-7.0 F60;

N240 X105.0 Y90.0;

N250 X-105.0;

N260 G98 X-50.0 Y-100.0;

N270 G80;

N280 G91 G30 X0 Y0 Z0;

N290 M06;换孔倒角刀

N300 G00 G90 G54 X50.0 Y-100.0 S300;

N310 G43 Z100.0 H04 M03 T05;

N320 G99 G82 Z-16.0 R-7.0 P500 F60;

N330 X105.0 Y90.0;

N340 X-105.0;

N350 G98 X-50.0 Y-100.0;

N360 G80;

N370 G91 G30 X0 Y0 Z0;

N380 M06; 换Φ10mm立铣刀

N390 G00 G90 G54 X0 Y0 S400;

N400 G43 Z0 H05 M03 T06;

N410 G00 X0 Y87.0;

N420 G01 Z -16.15 F40;

N430 M98 P0001;

N440 G00 Z100.0;

N450 G91 G30 X0 Y0 Z0;

N460 M06; 换丝锥

N470 G00 G54 G90 X50.0 Y-100.0 S60;

N480 G43 Z100.0 H06 M03;

N490 M29 S60;

N500 G99 G84 Z-30.0 R-7.0 F90;

N510 X105.0 Y90.0;

N520 X-105.0;

N530 G98 X-50.0 Y-100.0;

N540 G80;

N550 G91 G30 X0 Y0 Z0;

N560 M30; O0001;(子程序)

N010 G01 X60.0 Y87.0;

N020 G02 X102.77 Y20.52 R47.0;

N030 G01 X63.67 Y-65.34;

N040 G02 X30.0 Y-87.0 R37.0;

N050 G01 X-30.0;

N060 G02 X-63.67 Y-65.34 R37.0;

N070 G01 X-102.77 Y20.52;

N080 G02 X-60.0 Y87.0 R47.0;

N090 G01 X0;

N100 M99;

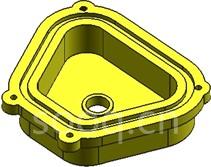

【例6-10】 在加工中心上加工图6-31所示的壳体零件,材料HT200。零件底面、圆孔及孔止口面已加工完成,现要求:铣顶面保证 尺寸, Ra3.2m。铣槽 , Ra6.3m,一次加工完成。钻攻4M10螺纹孔及孔口倒角。

该零件以底面孔和圆孔为主定位面,侧面采用定位螺钉为辅助定位,圆孔止口面为夹紧面。一次装夹后完成所有的加工内容。加工工艺与刀具如表2-32、表2-33。 工件坐标系设在工件中心,且离工件底面上方70.1mm处。槽中心线各基点的坐标为:a(60,87)、b(102.77,20.52)、c(63.67,-65.34)、d(30,-87)、e(-30,-87)、f(-63.67,-65.34)、g(-102.77,20.52)、h(-60,87)。

O1002;

N010 G40 G80 G17;

N020 G91 G30 X0 Y0 Z0 T01;

N030 M06; 换面铣刀

N040 G00 G90 G54 X0 Y0 S300;

N050 G43 Z0 H01 M03 T02;

N060 G01 Z-10.0 F30;

N070 Y87.0 F60;

N080 M98 P0001;

N090 G00 Z100.0;

N100 G91 G30 X0 Y0 Z0;

N110 M06;换中心钻

N120 G00 G90 G54 X50.0 Y-100.0 S1250 ;

N130 G43 H02 Z100.0 M03 T03;

N140 G99 G81 Z-15.0 R-7.0 F100;

N150 X105.0 Y90.0;

N160 X-105.0;

N170 G98 X-50.0 Y-100.0;

N180 G80;

N190 G91 G30 X0 Y0 Z0;

N200 M06; 换φ8.5mm钻头

N210 G00 G90 G54 X50.0 Y-100.0 S600;

N220 G43 Z100.0 H03 M03 T04;

N230 G99 G81 Z-30.0 R-7.0 F60;

N240 X105.0 Y90.0;

N250 X-105.0;

N260 G98 X-50.0 Y-100.0;

N270 G80;

N280 G91 G30 X0 Y0 Z0;

N290 M06;换孔倒角刀

N300 G00 G90 G54 X50.0 Y-100.0 S300;

N310 G43 Z100.0 H04 M03 T05;

N320 G99 G82 Z-16.0 R-7.0 P500 F60;

N330 X105.0 Y90.0;

N340 X-105.0;

N350 G98 X-50.0 Y-100.0;

N360 G80;

N370 G91 G30 X0 Y0 Z0;

N380 M06; 换Φ10mm立铣刀

N390 G00 G90 G54 X0 Y0 S400;

N400 G43 Z0 H05 M03 T06;

N410 G00 X0 Y87.0;

N420 G01 Z -16.15 F40;

N430 M98 P0001;

N440 G00 Z100.0;

N450 G91 G30 X0 Y0 Z0;

N460 M06; 换丝锥

N470 G00 G54 G90 X50.0 Y-100.0 S60;

N480 G43 Z100.0 H06 M03;

N490 M29 S60;

N500 G99 G84 Z-30.0 R-7.0 F90;

N510 X105.0 Y90.0;

N520 X-105.0;

N530 G98 X-50.0 Y-100.0;

N540 G80;

N550 G91 G30 X0 Y0 Z0;

N560 M30; O0001;(子程序)

N010 G01 X60.0 Y87.0;

N020 G02 X102.77 Y20.52 R47.0;

N030 G01 X63.67 Y-65.34;

N040 G02 X30.0 Y-87.0 R37.0;

N050 G01 X-30.0;

N060 G02 X-63.67 Y-65.34 R37.0;

N070 G01 X-102.77 Y20.52;

N080 G02 X-60.0 Y87.0 R47.0;

N090 G01 X0;

N100 M99;

声明:本网站所收集的部分公开资料来源于互联网,转载的目的在于传递更多信息及用于网络分享,并不代表本站赞同其观点和对其真实性负责,也不构成任何其他建议。本站部分作品是由网友自主投稿和发布、编辑整理上传,对此类作品本站仅提供交流平台,不为其版权负责。如果您发现网站上所用视频、图片、文字如涉及作品版权问题,请第一时间告知,我们将根据您提供的证明材料确认版权并按国家标准支付稿酬或立即删除内容,以保证您的权益!联系电话:010-58612588 或 Email:editor@mmsonline.com.cn。

网友评论

匿名:

相关链接

最新反馈

- 暂无反馈

无须注册,轻松沟通