埃马克电化学公司关于整体叶盘精密电解加工工艺综述

——EMAG ECM GmbH- A PECM Cost-Saving Approach to Blisk Manufacturing EMAG ECM GmbH, 2012

Abstract

摘要

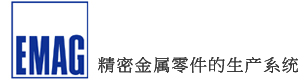

整体叶盘的出现是为了满足市场的需求,与传统转子叶片和轮盘分离的装配式叶盘相比,由于减少了传统连接中的榫头,榫槽等装配零件,叶轮边缘负载降低,重量减轻高达30%,同时由于避免了榫头气流损失也即减少动力消耗,从而也提高气动效率并显著提高功率,有助于减少燃油消耗和废气排放。追溯其发展历史最初应用到高压压气机以及商用压气机末端上。是现代燃气涡轮发动机中最具创新和挑战的零部件。

The emergence of BLISK(Bladed integrated Disk) is in order to meet the market demand calls, comparing with conventional separable assembled rotor blades and disk counterparts, due to the reduction in the conventional connector assembly parts of the disk lugs, blade root groove, etc.; the rim load lower. The essential advantages are that they reduce weight up to 30% as well as reduce aerodynamic losses by avoiding disk lugs air leakage flows, thus improve aerodynamic efficiency and the power output, specially it enables reduce in fuel consumption and exhaust gas volume emissions. Retracing the history of Blisk development, it’s application initially used in high-pressure compressors and commercial compressors. It is the most innovative and challenging components of modern gas turbine engine.

图1: 整体叶盘模拟图 Fig. 1: CAD Blisk

市场需求情况-应对2020年需求的挑战

Markt demond-Preparing for the Global Challenges of 2020

European aviation is experiencing a golden age which shows no sign of slowing. The continuous growth in world air transport - passengers and freight - experienced since the 1960s is set to continue at a rate of at least 5% a year over the next two decades. The latest Airbus forecasts indicate that this will mean a demand for 7600 new aircraft every decade - or a market estimated at 1300 billion Euros by 2019. As a vital sector in the European - and American - industrial dynamic, aircraft manufacture must therefore continue to innovate if it is to win these large markets.

自从1960年以来航空业一直维持每年近5%的持续的年增长率,欧洲航空空客业乐观的预测下一个12年直到2019年的平均年增长率会保持不变,这也就意味着在2020年前将会有7200架新的飞机需求(客运以及货运)/也即13000亿欧元的市场份额。想要赢得这个巨大的市场份额,无论欧洲还是美国都必须全面投入新的技术革新来争取。

The main objectives of the Aeronautics key action

35% reduction in production costs

20% reduction in development time

20% reduction in fuel consumption

Increased reliability

10 dB reduction in sound level

20% reduction in CO2 emissions

80% reduction in NOx

Optimization of airspace use

25% reduction in maintenance costs

Reduced rate of accidents

数据来源Quelle: http://ec.europa.eu/research/rtdinfo/en/28/aero1.html

航空业需要达到的重点行动目标

生产成本降低35%

开发时间减少20%

燃料消耗减少20%

提高可靠性

噪音水平减少10分贝

减少20%的二氧化碳排放量

减少80%的氮氧化物

优化空域使用

维护费用降低25%

降低事故发生率

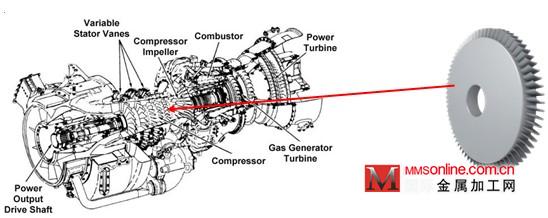

图2:世界人口每人公里数飞行预测

Fig.: Flight amount in personal-kilometer worldwide

Growth in the production and use of blisks becomes clearly apparent. The trend is driven

also by increasing use in commercial engines. In the face of aggravating competition, individual AND cost saving manufacturing processes and moreover complete tailor made short foot prints- process chains need continuous optimization to satisfy market requirements.

整体叶盘的生产及应用是显而易见的。这种趋势的主要缘由是来自民用需求。

面对激烈的市场竞争,独立并且经济的工艺是首选,特别是量身订制的缩短工艺路线路径的全套方案更需要优化以满足市场的需求

整体叶盘主要制造技术

Main approaches for manufacturing blisk airfoils

整体叶盘目前主要加工工艺

The major alternative process for blisk machining:

•高效整体铣削

High Performance overall milling

•多轴联动数控精密电解: 由于整体刀具成本的显著降低,电解以及精密电解正在发展成为高温合金材料整体叶盘最佳的加工工艺

Multi-axis linkage CNC PECM (precise electrochemical machining): Due to the significant tool cost saving, precise electro-chemical machining (PECM) is developing to become the most preferred manufacturing approach for blisk in nickel alloys.

埃马克电化学有限公司最新开发的PO 900 BF精密多轴联动高频窄脉冲电解加工中心及全套交钥匙工艺-从整体叶盘毛坯的初成行叶片套料加工(大量去除材料初步选择性的实现叶片扭曲角度以及叶片轮廓)直到最终叶片型面成型完整的工艺链工件交钥匙解决方案。

EMAG ECM GmbH developed its own new multi-axis PECM machining center and a whole tailor made process turnkey solution- from blisk rough majority material removing (masking roughing machining for majority material removing results in airfoil twisting pre-conture) till airfoil profile final conture.

1. 高效整体铣削

High Performance overall milling

This refers to cutting processes used to manufacture airfoils on 5- or 6-axis machine tools , with differentiation being made between rough and finish cutting. Typical processes of the kind are circular stagger milling in conjunction with high-performance tools and high-pressure internal cooling for the rough cut, The most common practice is point milling using a ball-end cutter and stripe or flank milling, etc., for the finish cut.

高效整体铣削技术是指在5或6轴加工中心加工上来进行叶片的粗加工和精加工。典型工艺是循环交错铣结合高效能的设备和高压力内部冷却进行粗切削,叶盘精加工最常见的做法是用球面铣刀点球铣,侧铣与条纹铣等。

2. 多轴联动数控精密电解: 由于整体刀具成本的显著降低,电解以及精密电解正在发展成为高温合金材料整体叶盘最佳的加工工艺

Multi-axis linkage CNC PECM (precise electrochemical machining): Due to the significant tool cost saving, precise electro-chemical machining (PECM) is developing to become the most preferred manufacturing approach for blisk in nickel alloys.

多轴联动数控精密电解加工技术综合了多轴联动计算机数控和精密电解加工(基于电化学阳极溶解的原理来去除金属材料)的加工两者技术特点,工具阴极无损耗,无宏观切削力,特别适宜加工压气机末端高温区高温合金或者钛合金的变截面扭曲叶片的高难度整体叶盘整体叶盘。

Multi-axis linkage CNC PECM (precise electrochemical machining) combined both advantages from CNC machining and PECM machining, there is not tool wear, no macro cutting force, especially suitable for high presuure compressor at end of the high-temperature zone with nikle alloy or titanium alloy of more twisted airfoil.

Precise electro-chemical machining (PECM) – an advanced technology for machining blisks

3.精密电解加工–先进的整体叶盘加工工艺手段

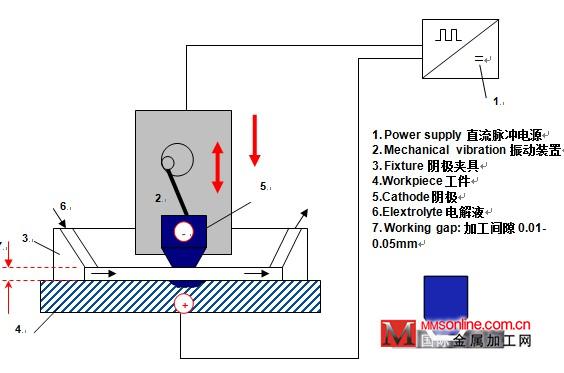

Precise electro-chemical machining (PECM) derives from the widely used electro-chemical

machining (ECM) technique. It is characterized by very small working gap between the electrode and the workpiece. This enables highly precise copy conformance of the workpiece shape to that of the cathode. Herewith, EMAG ECM GmbH develop its own cathode design software for airfoil radius or others profile zone compensation conformance during PECM Processes. Morevoer, this PECM process doesn’t generate any wear at the electrode, even when working on nickel alloys comparing with CNC milling process that are difficult to machine.

精密电解加工工艺(PECM)是源自于普通电解加工(ECM),在加工阴极与工件之间的加工间隙较与后者的主要特点是加工间隙很小。也因此可以达到良好的从阴极到工件复印效果。在这里需要强调的是,埃马克电化学公司开发了自己独立的阴极设计软件,此软件可以在精密电解工艺过程中对叶片的进排气R角以及相对型面区域进行自动补偿。另外,此工艺与传统的数控铣削工艺相比,乃至加工镍基合金材料的整体叶盘也不会产生任何阴极消耗。

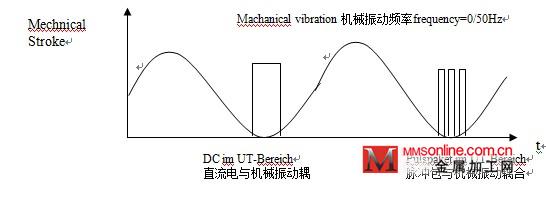

Because of the narrow working gap between electrode and workpiece, good exchange of the electrolyte is ensured only provided the electrode is set in an osccillating motion. In synchronism with the oscillating motion, a direct current pulse (material removal pulse) is superimposed and material is removed only when the gap is at its narrowest. This appreciably reduces the effective feed rate. EMAG ECM GmbH develp this technique with it new machine PO 900 BF with it the machining tolerances of airfoil ≤0,06mm (shape) and Surface quality of suitable materials of Ra ≤0,2 μmcan be reachable.

由于工件与电极之间较窄的加工间隙,电解液的充分交换需要通过电极的振动才能完成,在振动过程中,在电极与工件接触最近的时候或者说振动幅最大时配给电流,此电流进行材料去除加工, 显然整体的加工进给速度会降低,埃马克电化学有限公司最新开发的PO 900 BF精密多轴联动高频窄脉冲电解加工中心可以最终达到叶片型面轮廓精度≤0,06mm一般高温合金材料表面光洁度Ra ≤0,2 μm。

图3:精密振动电解加工原理 Fig. 3: PECM Eccentric vibration theory

图4: 机械振动与电脉冲配合的复合机械电加工

Fig. 4: Puls-ECM current combined with Oszillation (Puls-Packet)

4.工艺对比举例

Examples of Process Comparison

相比较高效整体铣削计算复杂,另外整体刀具加工成本也很高。

举例在加工整体叶盘直径约600mm,材料为高温合金,叶片数量70片以上,叶片单边尺寸面积在12cm2多轴联动数控精密电解与铣削的工艺路线以及成本对比见如下表格:

Comparing with the High Performance overall milling as well as its tooling cost is also very expensive. The following comparing sheet shows some simple process foot print and cost comparison between High Performance overall milling and Multi-axis linkage CNC PECM for blisk machining of a blisk with diameter around 600mm, material is nickel base alloy, the number of airfoils is more than 70, the machining area of each foil single side is around 12cm2 :

5. 埃马克多轴联动数控精密电解整体叶盘加工可达到的工艺指标

埃马克电化学有限公司最新开发的PO 900 BF精密多轴联动高频窄脉冲电解加工中心及全套交钥匙工艺-从整体叶盘毛坯的初成行叶片套料加工(大量去除材料初步选择性的实现叶片扭曲角度以及叶片轮廓)直到最终叶片型面成型完整的工艺链工件交钥匙解决方案。

EMAG ECM GmbH developed its own new multi-axis PECM machining center and a whole tailor made process turnkey solution- from blisk rough majority material removing (masking roughing machining for majority material removing results in airfoil twisting pre-conture) till airfoil profile final conture.

● 叶片型面轮廓精度≤0,06mm

Achievable tolerances of airfoil ≤0,06mm (shape)

● 一般高温合金材料表面光洁度Ra ≤0,2 μm

Surface quality of suitable materials of Ra ≤0,2 μm

● 采用数控多轴联动电解工艺进行叶片套料加工,其进刀速度≤ 2mm/min

EMAG Multi-axis linkage CNC machining with infeed rate for airfoil ECM rough machining step is ≤ 2mm/min.

● 采用数控多轴联动精密电解加工工艺,其进刀速度约为0,1-0,2mm/min(叶片套料加工余量1mm ),并不会因为叶片面积以及材料以及几何尺寸都会对进刀速度的提高产生显著影响。

EMAG Multi-axis linkage CNC machining with infeed rate for finish machining is 0,1-0,2mm/min. (around 1mm stock). In a wide range of geometries infeed is independent of foil area or size, this means cycle time is constant without increase.

● 埃马克多轴联动数控精密电解工艺是完整工艺,不需要之后抛光以及对于叶片进排气边缘进行再次加工

EMAG Multi-axis linkage PECM blisk machining process, there is no subsequent machining required like polishing or airfoil edge machining.

● 埃马克多轴联动数控精密电解工艺是完整工艺是刀具无损耗工艺,在同一型号叶盘下的所有叶片可以使用同一套阴极制具完成加工,并多次使用。

EMAG Multi-axis linkage PECM blisk machining process in principle is free of wear. This means hundreds of foils can be machined with the same tooling.

● 埃马克多轴联动数控精密电解机床的投资可以视客户具体加工整体叶盘的尺寸以及电流配备,电解液系统配备进行特制化量身订制的投资。

EMAG Multi-axis linkage PECM blisk machine investment costs depend on the size of the workpieces. Equipment is completely adjustable to customer requests regarding electrical power supply and filtration system.

图5: EMAG PECM PO 900 BF 精密五轴电解加工中心

Fig. 5: EMAG PECM PO 900 BF Machine Center

(埃马克公司供稿)

声明:本网站所收集的部分公开资料来源于互联网,转载的目的在于传递更多信息及用于网络分享,并不代表本站赞同其观点和对其真实性负责,也不构成任何其他建议。本站部分作品是由网友自主投稿和发布、编辑整理上传,对此类作品本站仅提供交流平台,不为其版权负责。如果您发现网站上所用视频、图片、文字如涉及作品版权问题,请第一时间告知,我们将根据您提供的证明材料确认版权并按国家标准支付稿酬或立即删除内容,以保证您的权益!联系电话:010-58612588 或 Email:editor@mmsonline.com.cn。

- 暂无反馈